Selecting the perfect partner for rigid boxes counts for a great deal. Many companies use strong first impressions with rigid boxes to protect products on the expanding U.S. market. A good Custom Rigid Box Manufacturer enables you to satisfy clients, manage expenses, and meet deadlines. A bad decision might result in unhappy customers, further expenses, and delays.

Every piece includes straightforward instructions you may start using right away as well as facts and figures. Simple language and short lines in the guide help teams to act quickly and stay away from often seen errors.

10 Tips to Pick the Right Custom Rigid Box Manufacturer

Details on capacity, materials, design, customization, compliance, pricing, delivery, client work, support, and green policies will be found here. Compare suppliers using these pieces of advice and pick one matching your brand, budget, and timeline. Ten distinct suggestions provided in this guide will assist you in selecting dependable Custom Rigid Box Manufacturers.

1. Evaluate Manufacturing Capacity.

Enquire about the daily factory output of boxes and how large orders are handled. Cutting errors and accelerating work are achieved by a plant using automated lines. You need to have exact daily and weekly output figures so that you may align manufacturing to your release plan. A provider unable to scale will compel you to hurry or pay more for quick runs.

A strong Custom Rigid Box Manufacturer will share capacity numbers and show how they scale for big runs. The provider’s evidence of their ability to meet your deadline will help you feel more certain.

- Request for daily capacity (e.g. 50,000 cartons a day).

- Lead times (generally 3–6 weeks) should be inquired about.

- Enquire whether they use automated cutting and folding lines.

2. Verify Material Quality

Choice of material has an impact on look, cost, and strength. Custom Magnetic Closure Boxes employ chipboard or paperboard between 800gsm and 2000gsm. Thicker boards provide a high end feel and safeguard heavy objects. Request samples and examine them using your product. Know whether the board will hold up in actual life by testing how it responds to humidity and drops.

Recycled or certified paper is available if you want green packaging. A dependable Custom Rigid Box Manufacturer will enable you to evaluate materials and justify trade-offs between price and lifespan so you can select the most appropriate choice for your product. To prevent surprises when cartons move or remain in a warehouse, use actual tests.

- Ask for drops and crush test samples.

- Note thickness ranges: 800 gsm, 1000 gsm, 1200 gsm, 2000 gsm.

- Inquire about recycled material and credentials.

Table: Common Materials in Rigid Boxes

| Material | Thickness | Durability | Cost Impact |

|---|---|---|---|

| Chipboard | 1200gsm | High | Medium |

| Paperboard | 800gsm | Medium | Low |

| Recycled Board | 1000gsm | High | Medium |

3. Review Design Capabilities

Design influences consumers’ perceptions of your goods. Good design teams produce mockups and proofs aligned with your logo and brand colors. Check with the vendor whether 3D mockups and color proofs are provided so that you can see the appearance prior to production. Examine offset, digital, foil stamping, and other print processes to learn how each one affects cost and finish.

A great design team enables you to create Custom Rigid Gift Boxes that sell on the shelf and look amazing online. A talented Custom Rigid Box Maker will present design samples and clarify how each print method impacts cost and appearance so that you can pick the most suitable fit for your brand. Request to view prior projects appropriate for your budget and tastes.

- Ask for three-dimensional samples and color proofs.

- Examine printing choices: offset, digital, foil stamping.

- Request case studies and samples from prior designs.

4. Examine customizing possibilities.

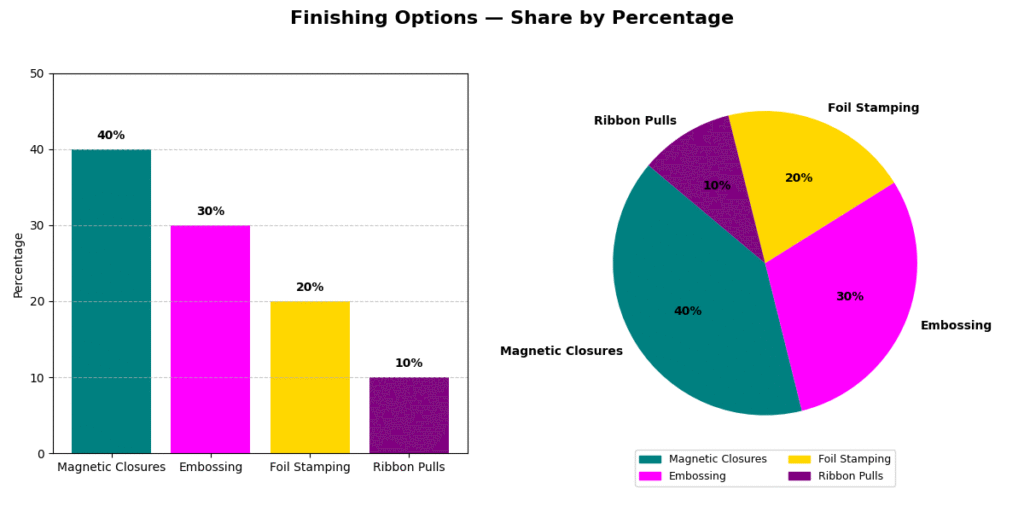

Personalizing your product helps with unboxing moments and gives it a special touch. To boost perceived value, brands include magnetic closures, ribbon pulls, embossing, and unique inserts. Find out which aspects the supplier produces internally and which they contract out. Know how every component affects the unit cost and delivery time so you may plan your budget and timetable; a provider that processes more stages in-house will shorten lead times and minimize errors.

A clear list of possibilities assists you compare estimates and bypass concealed charges. A great Custom Rigid Box Manufacturing will include possibilities and demonstrate how each feature affects unit cost and lead time, allowing you to plan your budget and maintain your launch on course.

- Look at the following: magnetic closures, embossing, foil stamping.

- Ask regarding Custom Packaging Inserts and die-cut trays.

- Request cost estimations for every component.

Popular Custom Features in Rigid Boxes USA

5. Check Compliance Standards

To avoid recalls and penalties, adhere with the instructions. Special packing standards apply to food, cosmetics, and medicines. Ask the provider whether they use food-safe adhesives and FDA-approved inks. Seek ISO or ASTM certificates attesting to quality control. Non-compliance can result in product holds and public recalls, hence financial burden and lost trust.

Request last test reports and audit results to see evidence of safe conduct. A reliable Custom Rigid Box Manufacturer will share compliance papers and clarify how they evaluate materials to meet guidelines, thereby keeping your product legal and safe. Store duplicates of every certificate in your records for buyer verifications and inspections.

- Inquire regarding food contact materials authorized by the FDA.

- Request ISO 9001 or ASTM compliance records.

- Inquiries on current audit or test reports.

6. Contrast Price Models

Ask for straightforward pricing that reveals how volume and features affect pricing. Ordering more Drawer Rigid Boxes causes the unit price to fall. At low volume, a basic rigid box could cost $1.50–$2.50; at greater volume, this cost might fall to $1.20–$1.80. Accessories like foil stamping or magnetic closures increase the price. Request a complete cost sheet listing material, printing, finishing, tooling, and shipping so you may fairly evaluate offers.

Look out for covert costs such as setup or rush costs. A simple Custom Rigid Box Manufacturing will show how volume orders reduce unit cost and will describe any one-time expenses so that you may budget without surprises. Run a basic break-even check for several order volumes using the cost sheet.

- Request a thorough cost breakdown and cost per unit.

- Examine pricing for ten thousand and fifty thousand units.

- Inquire about sample charges and tooling costs.

7. Assess Delivery and Logistics

Delivery counts as much as generation. Inquire whether the supplier sends from international or from U.S. warehouses. Local warehouses help to reduce customs risk and transit time. Enquire about tracking systems and shipping partners so you can track every delivery. Late packaging can cost marketing dollars and postpone product launches. A supplier with excellent logistics will present alternatives for air or sea freight and assist you in selecting the most cost- and speed-efficient path.

Reliable Manufacturing will describe transportation choices, display transit times, and provide solutions for urgent needs so that you may satisfy launch dates and retain consumers happy. In case they export cross-border, inquire about customs paperwork management.

- Inquire about warehousing locations and delivery schedules.

- Ask which carriers they use and if tracking is available.

- Enquire about lead times for expedited orders.

8. Review Client Portfolio

Review past work to evaluate fitness. request case studies highlighting comparable goods and budgets. Anyone who focuses on cosmetics, electronics, or premium goods will know how to fulfill precise criteria. Request fresh client references and contact information so you may find out how the supplier handled tight deadlines and design modifications.

See how they tackled issues in previous projects and kept high quality under pressure. A verified Custom Rigid Box Manufacturer will share customer stories and show how they overcame actual problems to build confidence in their process and prevent surprises. References should be used to inquire about quality inspections and on-time delivery.

- Ask for customer references and case studies.

- Examine work in your industry: cosmetics, electronics, jewelry.

- Ask how they addressed past production problems.

9. Evaluate Customer Support

Projects remain on track with good assistance. Find out if the provider designates one account manager in charge of production, design, and delivery of your Foldable rigid boxes. Quick responses speed choices and stop errors. Inquiring of them on design change management during production as well as approval confirmation.

Poor communication slows launches and increases expenditures; good updates help your team to stay aligned and on schedule. A responsive Custom Rigid Box Manufacturer will solve problems quickly so your project stays on schedule and your team stays calm by keeping you updated at every stage. Ask for a sample production schedule with milestones so you can plan internal work.

- Ask about account managers and reaction times.

- Inquire about their approach to approvals and modifications in design.

- Request a sample production schedule with milestones.

10. Think About Sustainability Methods

Many consumers as well as long-run brands depend on sustainability. Inquire whether the provider employs biodegradable coatings, water-based inks, and recycled board. See whether they release sustainability reports and monitor energy and waste consumption. Many consumers pick companies that employ green packaging; this decision helps to increase sales and loyalty.

Request certificates proving low carbon behavior or recycled content so you may substantiate your assertions to clients. While keeping costs clear and predictable, a green Custom Rigid Box Manufacturer will assist you in satisfying client expectations and lowering the environmental effect of your company. Connect with eco-minded consumers by including sustainability claims in your product narrative.

- Inquire about ecologically friendly inks and recycled content.

- Request certificates or sustainability studies.

- Ask how they lower energy consumption and waste.

Table

| Category | Priority | Key check | One-line supplier question |

|---|---|---|---|

| Manufacturing Capacity | 5 | Daily/weekly output; automation | “What is your daily output and peak weekly capacity?” |

| Material Quality | 5 | GSM range; drop/crush tests | “Can you provide 800–2000gsm samples and drop/crush test results?” |

| Compliance Standards | 5 | FDA/ISO/ASTM evidence | “Do you have FDA-safe inks and ISO 9001 / ASTM certificates?” |

| Design Capabilities | 4 | 3D mockups; print methods | “Do you provide 3D proofs and color-matched print proofs?” |

| Customization Options | 4 | In-house vs outsourced features | “Which features are in-house and what are per-unit costs?” |

| Price Models | 4 | Volume tiers; tooling fees | “Provide full cost breakdown for 10k and 50k units.” |

| Delivery & Logistics | 4 | Warehousing; carriers; expedited lead times | “Where are warehouses located and what carriers do you use?” |

| Customer Support | 4 | Single account manager; approval flow | “Who will be our account lead and typical response time?” |

| Client Portfolio | 3 | Case studies in your industry | “Share 2–3 case studies for cosmetics/electronics/jewelry.” |

| Sustainability Practices | 3 | Recycled content; eco inks | “Provide certificates for recycled content and sustainability reports.” |

Ready to Ship on Time? Partner with Us Today

Select a partner that satisfies your demands for quality, cost, and speed. A powerful Custom Rigid Box Manufacturer will offer design proofs, compliance documents, clearly set prices, delivery schedule, material samples, and capacity numbers. Compare suppliers using the ten points listed above to choose the one best suited for your brand and deadline. Contact a reliable custom rigid boxes provider today to ask samples, a thorough estimate, and a production schedule so you may confidently advance your product launch.

FAQs

What should I ask a box manufacturer before ordering?

- MOQ

- Material options

- Lead times

- Customization possibilities

- Sample availability

What industries use custom rigid boxes?

- Cosmetics

- Jewelry

- Electronics

- Luxury gifts

What is an acceptable defect rate?

Most manufacturers aim to keep defects below 0.5%, and they offer warranties for damaged units.