Idaho boasts a vibrant business scene. Over 65% of local companies choose unique packaging to build their brand. Specialized projects grew by 15% in recent years. Local suppliers work hard to meet demand. They also cut production time by 30%. These figures show that custom rigid boxes are a hot commodity here. With more than 262,248 businesses in this US state, growing your business is not a simple target to achieve. For this purpose, this wholesale Custom Rigid Boxes Buying Guide for Idaho businesses works for big businesses and small brands that want to stand out.

Many local firms see a 10% rise in packaging orders each year. The Gem State’s population grows by approximately 5% yearly. With these facts, let’s dive in and make your brand shine!

Idaho Custom Rigid Boxes Buying Guide

Below, you will find sections that offer important data, clear tables, and actionable tips that work for businesses to see How To Buy Printed Custom Rigid Boxes In Idaho.

1. Market Dynamics

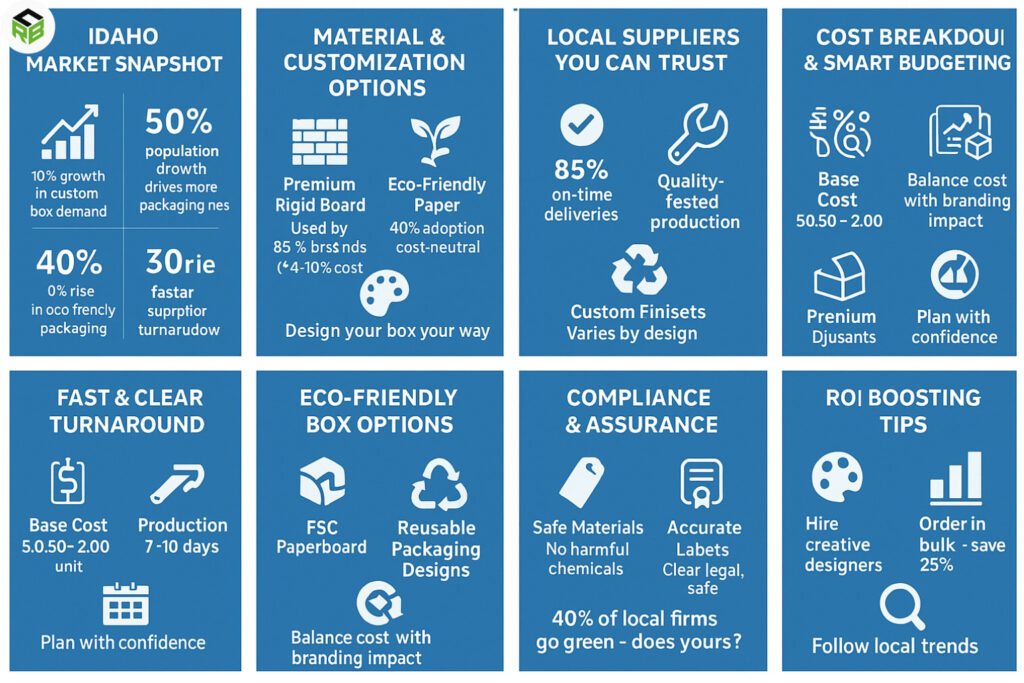

Idaho’s market trends guide your packaging decisions. Local businesses report a 10% yearly boost in custom packaging orders. The steady 5% population growth keeps demand high. This growth pushes suppliers to offer fast and flexible service.

Consider these facts:

| Metric | Figure | Description |

|---|---|---|

| Local packaging demand growth | 10% increase | Year-over-year surge in custom box orders |

| Annual population growth | 5% increase | Steady growth that boosts market demand |

| Adoption of eco-friendly options | 40% increase | Percentage of firms that choose green packaging |

| Reduction in turnaround time | 30% reduction | Improved processing speeds from local suppliers |

These bright trends ensure that investing in quality packaging gives your brand an edge.

2. Material Quality & Customization Specifications

The choice of material makes a big difference. The Gem State companies need boxes that protect and look amazing. Local manufacturers offer 100% tailored options to meet your exact design needs. You can pick special finishes, textures, and custom shapes. For this, you can order Die-Cut Embossed Custom Rigid Boxes with Spot UV Finishing.

Below is a summary of options:

| Option | Material | Local Adoption | Cost Impact |

|---|---|---|---|

| Premium Rigid Board | Durable cardboard | 85% of high-end brands | +4-10% for luxury finish |

| Eco-friendly Material | Recyclable paper products | 40% of Idaho companies | Cost-neutral with added value |

| Custom Finishes | Matte or glossy surfaces | Sought by boutique brands | +Variable based on design |

These options let you choose a style that suits your needs and protects your products.

3. Local Supplier Landscape and Manufacturer Reliability

Local suppliers are a good bet. They show strong performance and offer quick responses. More than 85% of the vendors complete orders on time. They use rigorous quality tests to meet your standards.

Local suppliers focus on:

- Quick communication and personalized service.

- Reliable delivery schedules.

- High quality standards that you can trust.

A solid supplier makes a huge difference when you need Full-Color Inside-Out Printed Custom Rigid Boxes in bulk that win customer confidence.

4. Price Analysis and Budgeting Considerations

Cost is a major factor. We break down the main price drivers to help you set a budget. Many businesses face a 4-10% increase for premium finishes. Bulk orders may cut costs by as much as 25%.

The cost analysis shows:

| Cost Component | Impact on Price | Market Example |

|---|---|---|

| Basic Production | Base price | Approximately $0.50 – $2.00 per unit |

| Premium Finishes | +4-10% increase | Adds a touch of luxury to standard boxes |

| Custom Artwork & Inserts | Variable cost | Special designs that boost visual appeal |

| Bulk Discounts | -Up to 25% saving | Long-term orders reduce costs significantly |

Budget wisely by weighing these costs against improved brand value and promotional gains.

5. Production Timelines and Turnaround Expectations

Time matters for every project. Local manufacturers shorten turnarounds by about 30%. You can count on a clear schedule for your order.

A typical timeline looks like this:

- Design Approval: 3-5 business days.

- Manufacturing Cycle: 7-10 business days.

- Quality Check & Delivery: 2-3 business days.

6. Sustainable and Eco-Friendly Packaging Options

This US State goes green. Environmental care is a must for many companies. Local brands choose Bespoke Magnetic Closure Rigid Boxes for Corporate Gifting made from recyclable materials. Approximately 40% of manufacturers use eco-friendly practices.

Eco-friendly choices include:

- FSC-Certified Paperboard: A mark of quality and care for nature.

- Recyclable Inks and Finishes: These reduce harmful waste.

- Reusable Designs: Support sustainable consumption.

These choices boost your brand’s eco-friendly image and attract customers who care about the planet.

7. Regulatory, Compliance, and Quality Assurance Considerations

Regulations keep products safe and trustworthy. Manufacturers follow strict guidelines. Over 70% of companies meet robust quality assurance standards.

Key points include:

- Material Safety: Ensures no harmful chemicals exist.

- Accurate Labeling: Proper information protects both you and your customers.

- Quality Certification: Certificates confirm that high standards are met.

This compliance gives you peace of mind. Your packaging meets local and national rules. That trust builds a stronger relationship with your buyers.

8. Expert Tips and Local Insights for Maximizing ROI

Expert advice can boost your returns. Local businesses see an ROI increase of up to 50% after switching to premium packaging. Top tips include:

- Work with Creative Designers: They bring fresh ideas to life.

- Order in Bulk: This strategy can cut your costs by up to 25%.

- Stay Updated on Local Trends: Knowing what competitors do keeps you sharp.

- Analyze Your ROI Data: Small improvements in packaging can lead to big gains.

Local experts often stress that quality packages win customer hearts and improve sales. These friendly tips can help you build a memorable brand experience.

Closing Remarks

Boost your brand today! Reach out to local suppliers and request sample boxes. Discuss your creative ideas with their experts and compare offers. Take a step toward standout Custom Packaging Inserts that wins new customers. Bright ideas and quality products lead your business to new heights!

With this custom rigid boxes buying guide for ID businesses. You now see the market trends, materials, suppliers, pricing, production times, green options, regulations, and expert insights. Use these insights to choose the perfect packaging solutions to boost your brand and stand out locally.

FAQs

How can I order eco-friendly boxes in the Gem State?

Many suppliers offer eco-friendly boxes made from FSC-certified, recyclable materials. Search for “eco-friendly custom rigid boxes for small and eco-conscious businesses in Idaho”. By doing so, you can view the best options with sustainable features.

What are the trends in rigid packaging?

- Sustainability & Eco-Friendliness

- Light-weighting

- Innovative Design & Personalization

- Smart Packaging Technologies like e.g., QR codes, NFC chips

- Barrier Technologies for Extended Shelf Life

- E-commerce Optimized Packaging

What is the difference between flexible and rigid packaging?

- Material Composition: Rigid packaging uses solid stuff like glass, metal, or chipboard. But flexible packaging uses soft materials like film, foil, or thin plastic.

- Durability: Wholesale bespoke rigid box packaging for corporate gifting stays strong and doesn’t break easily. Meanwhile, flexible packaging is lighter but can tear or get holes more often.

- Weight & Storage: Rigid box packaging weighs more and needs more space. In contrast, flexible packaging is light and easy to squeeze into small spots.

- Cost: Rigid packaging costs more because of the materials and how it’s made. On the other hand, flexible packaging is cheaper to make and ship.

- Environmental Impact: High-End Custom Rigid Packaging for Unforgettable Unboxing Experiences can be reused or recycled. Still, flexible packaging makes more waste, though it uses fewer materials.

- Product Protection: Rigid packaging protects breakable items better. Yet, flexible packaging blocks air and moisture but doesn’t guard against hard hits as well.

- Consumer Convenience: Rigid packaging feels strong and you can reseal it easily. Instead, flexible packaging is simple to carry and great for one-time use.

Can I personalize every aspect of my box?

Yes! You can customize almost every detail. Local makers let you pick the artwork, colors, textures, and special add-ons. They now give fully custom packaging options. To find the right fit, try long search terms like “custom high-end personalized rigid box packaging solutions in Idaho.”

What are the major specs of a rigid box?

Here are the major specs that you should consider:

- Material: High-strength chipboard/grayboard with custom paper wrap

- Thickness: 1.5–5 mm (board gauge)

- Size & Style: Custom dimensions; separate lid or telescoping

- Finish: Matte/gloss/soft-touch; foil or emboss accents

- Interior: Plain or printed lining; foam or velvet inserts

- Printing: CMYK or spot colors; optional UV coating

- Closure: Magnetic strips, ribbon pulls, or tuck-in flaps

- Capacity: Holds ~1–10 kg; transit-tested

- Extras: Window cut-outs, die-cuts, QR/NFC tags