Texas businesses value quality, efficiency, and local flavor. It stands out with its booming industrial market, where the packaging sector grows by 25% every decade. Here, local manufacturers serve 30% of the national packaging volume and keep production lead times at 7–12 days on average. With more than 2.9 million business entities, growing your brand is not an easy target. You can use catchy packaging for this purpose. This Custom Rigid Boxes Acquiring Guide for Texas businesses will show you how to get boxes that can boost your company. Let’s explore how you can confidently acquire custom printed rigid boxes wholesale that suit your needs.

Texas Custom Rigid Boxes Acquiring Guide

1. Understanding the Texas Market Landscape

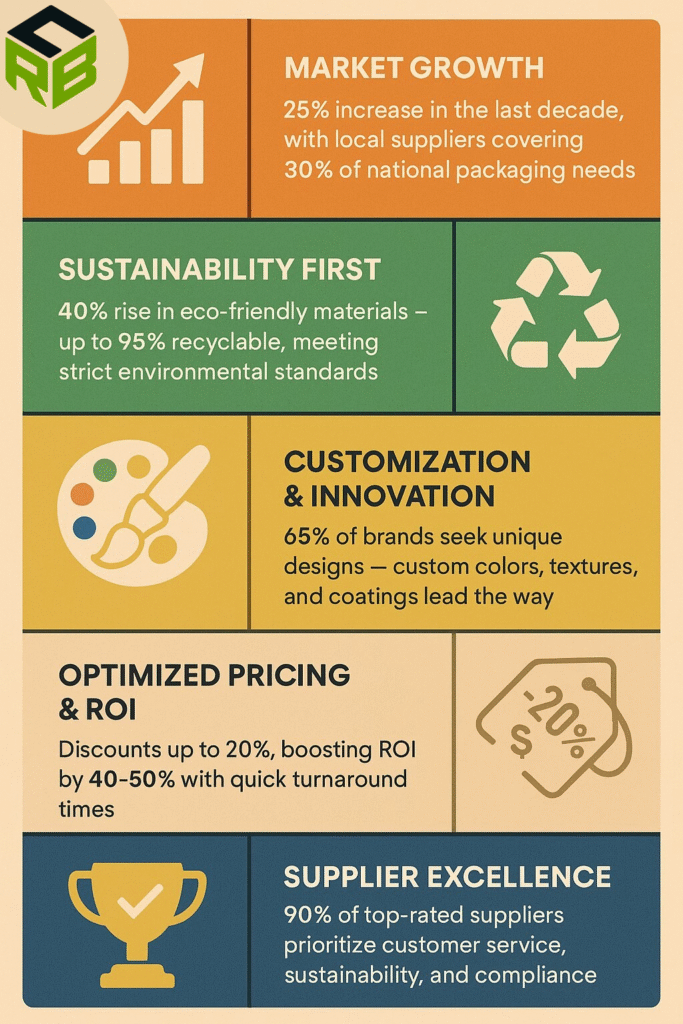

This US State boasts a dynamic business environment where packaging matters. Local companies support an industry that has shown a 25% growth in the last decade. You see aggressive competition and a business-friendly climate that drives innovation.

Local market trends demonstrate that nearly 30% of national packaging volume comes from suppliers. Small business owners and large industrial players thrive in a market that embraces locally sourced production. When you buy, you tap into a network of creativity, speed, and a solid industrial foundation. Moreover, Texas’ strategic position serves the entire nation, making your decision even more critical for speedy delivery and consistent quality.

2. Regulatory Considerations and Compliance

Manufacturers closely follow federal and state guidelines. Government bodies push for strict quality and safety standards for packaging, and companies stick to these requirements. Manufacturers have adapted to 15% stricter environmental standards over the years.

Local guidelines ensure that your Custom Rigid Boxes with Foil Stamping & Letterpress Detailing meet regulations on material safety, recyclability, and proper labeling. Agencies frequently update these rules to protect workers and consumers. You must check with your supplier to confirm that your packaging design complies with these standards, ensuring no hiccups during transport or when your product lands on shelves.

3. Material Selection and Quality Metrics

Selecting the right material lays the foundation of great packaging. Many businesses now favor eco-friendly and durable materials. For example, local production using recycled paper and kraft boards has increased by 40% in recent years.

Quality matters not only in feel and durability but also in how well Elegant Foldable Rigid Boxes with Personalized Die-Cut Designs protect your product during transit. Compare material quality metrics such as strength, water resistance, and print quality. Check sample products, and ensure that you consider the sustainability of the materials. Use the following table as a quick snapshot:

| Metric | Average |

|---|---|

| Eco-friendly Material Usage | 40% increase year-over-year |

| Material Durability | High tensile strength tested at >500 psi |

| Print & Color Quality | Consistent with industry standards |

| Recyclability | 95% materials recyclable |

This table helps you evaluate the material performance and make a knowledgeable decision that safeguards both your product and this US’s environment.

4. Customization Options and Design Flexibility

Brands require a distinctive look. Local suppliers offer a range of customization options that reflect regional style and functionality. Currently, 65% of businesses demand visually unique designs that stand out on the shelf.

When you’re thinking about different design ideas, consider choices like custom colors, raised textures, and special coatings. These features help your packaging match your brand’s style while making the unboxing moment feel exciting and memorable.

On top of that, local manufacturers use advanced digital printing methods. These tools make sure your images look sharp and your colors stay bright—even when Bespoke Custom Rigid Boxes with Unique Shape and Add-On Options go through tough shipping conditions. As a result, your packaging stays eye-catching and strong, no matter where it travels.

Moreover, engaging with a supplier who understands Texas culture can add that extra local touch that resonates with your customers. Dont underestimate the customuization importance of this Custom Rigid Boxes Acquiring Guide.

5. Pricing Structures and Cost Analysis

Companies operate in a tough market and their prices often indicate how they leapfrog others. To make a smart decision, you should know what variables affect the price, like the materials, the volume of material, and the finish. Also, competition in Texas has helped lower prices by about 10% recently. This means buyers can often get better deals than before.

Below is an example table outlining typical cost breakdowns for custom packaging boxes:

| Parameter | Typical Value |

|---|---|

| Base Price per Box | $0.50 – $1.25 |

| Custom Design Fee | $100–$300 per project |

| Order Volume Discount | 5–20% for bulk orders |

| Shipping Lead Time Cost | Varies; average lead time 7–12 days |

This table gives you a clear picture of pricing structures. Compare quotes, and ensure transparent breakdowns so you know exactly where every dollar goes. Additionally, pay attention to return on investment (ROI) benefits—many businesses see ROI improvements of 40–50% thanks to high-quality packaging that boosts brand perception.

6. Production Lead Times and Order Volume Considerations

Texas manufacturers work hard to keep lead times short. Many facilities deliver orders within 7–12 days, thanks to streamlined production methods and a strong local supply chain. When you place a bulk order, consider how such lead times affect your inventory planning.

Here’s a table to easily compare lead times based on order volumes:

| Order Size | Lead Time Estimate | Notes |

|---|---|---|

| Small Orders (< 500 boxes) | 7 days | Quick turnaround ensures small batches arrive fast |

| Medium Orders (500–2000 boxes) | 8-9 days | Efficient planning and production enable quick delivery |

| Large Orders (>2000 boxes) | 10 days | Increased setup time for large runs but still efficient |

Using real numbers helps you understand when to place orders and plan your marketing and distribution effectively. Don’t forget to communicate regularly with your supplier about any potential delays or large shifts in demand.

7. Sustainability and Eco-friendly Practices

Sustainability takes center stage in packaging. These days, nearly 80% of manufacturers use eco-friendly ways to make their products. Because of this, they protect the environment and also attract customers who want to lower their carbon footprint.

At the same time, this shift shows that more companies understand the value of going green. Instead of harming the planet, they choose smarter ways to make their products.

When you pick a supplier, ask what they do to help the environment. Also, check if they have certifications that show they use recycled materials, safe inks that break down naturally, or clean energy during production. In fact, many partners already use better technology that cuts down on waste and saves energy. Using practices can boost your brand’s reputation and potentially qualify you for local green business incentives.

8. Supplier Reputation and Customer Service Insights

In Texas, supplier reputation plays a major role in long-term business success. Local research shows that 90% of top-rated Texas packaging suppliers invest heavily in customer service and after-sales support. Work closely with suppliers who offer transparent communication, detailed order tracking, and robust guarantees.

Be sure to ask for testimonials and client case studies, and if you can, visit the manufacturing facility. Also, a supplier who listens to feedback will make sure you get a steady supply of good-quality products. This way, you can feel confident in what you receive every time. Businesses value relationships that deliver both reliable products and a smooth customer experience.

Build partnerships with suppliers who understand your unique needs and invest in future collaborations.

9. Packaging Innovations and Technological Advancements

Suppliers use new ideas that improve quality and save time. For example, digital printing, automation, and better production lines have made their work faster and more reliable. In fact, some reports show that automation in packaging grew by 50% last year.

Therefore, look for suppliers who use advanced machines to make printing and cutting more precise. Plus, new features like interactive packaging or augmented reality can make products more interesting for customers. These technologies not only speed up production but also let you customize products in exciting ways.

Also, watch for new trends so you can take advantage of the latest improvements. Companies lead with creative packaging that follows national trends while adding a unique local touch.

10. Final Considerations and Strategic Buying Tips

Buying custom rigid boxes in Texas requires a strategic approach. Follow these steps:

- Research the market: Understand local trends and reliable suppliers.

- Check regulations: Stay updated with Texas-specific guidelines.

- Focus on materials: Prioritize quality and eco-friendly options.

- Plan for production: Factor in realistic lead times and bulk order benefits.

- Leverage technology: Opt for suppliers who innovate and create unique designs.

When you base your decision on clear criteria, you can maximize your ROI. Statistics show that businesses embracing these strategies can see up to 40–50% improvement in overall packaging effectiveness. Adopting these buying tips creates a competitive advantage and builds reliable brand identification in the marketplace.

Before you make your final choice, compare several quotes and make sure everything is clear. Also, ask to see detailed portfolios. By doing these things, you will find it easier to ask for better prices and also create good, long-lasting connections with your suppliers. In addition, working this way helps both sides trust each other more. As a result, you can keep a strong and helpful relationship that lasts for years.

Custom Rigid Boxes Acquiring Guide Conclusion

By focusing on good materials, eco-friendly methods, and fast delivery times, you improve your brand and connect with this US State’s lively local market. Also, you now have a clear plan to get these boxes because of this Custom Rigid Boxes Acquiring Guide for TX businesses that show the State’ high quality and creative spirit. So, enjoy making smart, confident choices that help your business grow in the Lone Star State!

FAQs

Which materials do Texas businesses prefer for custom rigid boxes?

Many companies have shifted to eco-friendly materials. For instance, usage of recycled kraft paper and sustainable board materials has increased by 40% recently. This change meets both environmental standards and quality expectations.

What steps ensure that custom rigid boxes meet Texas regulations?

- Research Applicable Guidelines: Review both federal and Texas-specific packaging and safety regulations.

- Select Trusted Suppliers: Start by picking suppliers who have the right certificates and follow strict rules carefully. This helps you work only with reliable partners.

- Check Material Certifications: Then, make sure every packaging material has proper certificates that prove they are eco-friendly and good quality. This step is important to avoid problems later.

- Perform Regular Quality Testing: After that, test the materials often to see if they are strong and safe. Regular checks help catch issues before they become big problems.

- Ensure Proper Labeling: Also, double-check that the boxes show all the labels needed. These labels must tell what’s inside and include safety and rule information.

- Stay Updated on Regulatory Changes: Moreover, watch for any new rules from agencies. Staying informed means your work always follows the latest laws.

- Consult Regulatory Experts: Finally, talk to experts who know Texas packaging laws well. Their advice can help you avoid mistakes and stay on the right track.

What is rigid packaging?

It relates to packing done with sturdy and hard stuff such as glass, metal or tough plastics like PET or HDPE. It guards items through their trip from factory to customer as well as making stores look more appealing by showing the products off right.

What is the difference between rigid and semi rigid packaging?

- Structural Integrity: Rigid packaging keeps its shape firmly even when pressed, giving the best protection. On the other hand, semi rigid packaging bends a little but still holds its general shape well.

- Material & Weight: Tailor-Made Rigid Brand Packaging with Custom Packaging Inserts

uses thicker and stronger materials. It can make it heavier and bulkier. In contrast, semi rigid packaging uses lighter materials that still provide enough strength without adding too much weight. - Cost & Manufacturing: Because rigid packaging is built tough, it usually costs more to make and needs more work during production. Meanwhile, semi rigid packaging is cheaper to produce and easier to manufacture.

- Environmental Impact: Although quite often rigid packaging is fully recyclable, it employs more material and generates more waste. On the other hand, semi-rigid packaging uses fewer materials, reducing costs and being more environmentally friendly but may only be partially recycled.

- Application Suitability: When it comes to fancy, high-end products that need strong protection and a nice look, rigid packaging works best. However, semi rigid packaging suits everyday items where you need a mix of strength and some flexibility.