North Carolina pulses with a vibrant manufacturing scene that fuels businesses across the state. Companies here value quality, efficiency, and creative branding, which makes premium packaging a must-have. This Custom Rigid Boxes Obtaining Guide for North Carolina companies caters to small businesses and large enterprises alike that search for affordable custom rigid packaging boxes in North Carolina.

You can count on each part to give you useful tips and clear facts that help you make smart buying choices. Now, let’s dive into the world of custom rigid boxes that do more than look good—they also boost the local economy.

In Tar Heel State, manufacturers play a big role in keeping the economy strong. In fact, the manufacturing industry adds over 13.3% to the state’s GDP. Even better, there are more than 9,000 active production companies working across the state.

North Carolina Custom Rigid Boxes Obtaining Guide

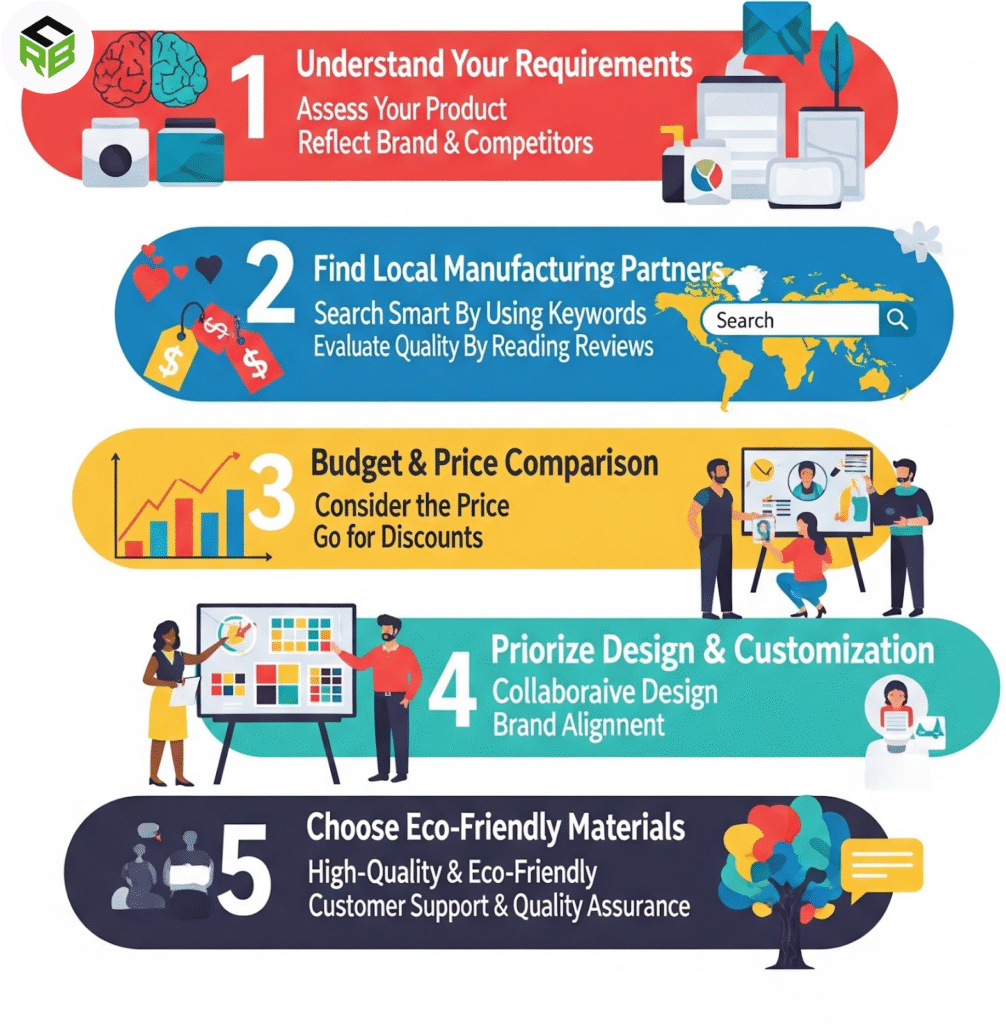

1. Understanding Your Packaging Requirements

Begin by analyzing your product’s dimensions, protection needs, and flair. Use simple questions like: “What shape fits my product best?” and “How will my branding appear on the box?” You decide if you need a sturdy box for luxury cosmetics or a colorful design for a seasonal product launch. Consider the local context as well; businesses often lean toward packaging that reflects modern design trends combined with a nod to regional craftsmanship.

Make a clear list of product needs and design ideas, then look at how they match up with what your competitors offer. For example, many small boutique shops in Charlotte like boxes that add a rich and fancy touch to their products. On the other hand, manufacturers in Raleigh often choose practical designs over fancy styles.

By setting clear needs early on, you make your search easier. As a result, you’ll save time in the next steps and stay focused on what really matters.

2. Researching Local Manufacturing Partners

Scout out local manufacturers that offer top-quality custom rigid boxes. Use search terms like “custom printed luxury rigid packaging boxes North Carolina” or “high-quality custom rigid boxes for small business in North Carolina.” Compare portfolios, testimonials, and production capabilities. Ask vendors how they achieve a production lead time of 7-12 days and what technologies they use.

As you narrow down your options, make sure each manufacturer has strong local connections. In this area, nearly 9,000 local manufacturers work hard to stand out, which means you’re more likely to find a partner that cares about quality and accuracy. Next, take time to read reviews and ask for sample orders. This extra step helps you see which partner fits your needs best. Plus, it helps you trust the local skills and experience even more.

3. Budgeting and Price Comparison

Evaluate your budget carefully before reaching out to premium rigid box packaging services in North Carolina. Figure out the cost per box and the full project cost early on. Be sure to include clear lines for design, printing, and shipping. These details give you a full picture of the budget. That way, you can bargain with more confidence and avoid any surprise costs later in the process.

A helpful approach is to prepare a budget table like the one below:

| Budget Component | Estimated Cost | Notes |

|---|---|---|

| Design & Artwork | $100 – $500 | Free design support sometimes available locally |

| Box Production (per unit) | $1.00 – $1.50 | Volume discounts may apply; use small order trends |

| Shipping | $50 – $150 | Charges depend on quantity and destination |

| Miscellaneous Fees | $25 – $75 | Include customization or extra finishes |

This table clarifies how pricing elements add up. This robust market ensures competitive pricing through high-volume orders and advanced production technologies, which sometimes lower costs by up to 15% compared to larger markets.

4. Design, Customization, and Brand Identity Alignment

Design plays a crucial role in how customers perceive your brand. Emphasize that every choice—from color palettes to finishing touches—should reflect your brand identity boldly. Use specific phrases like “custom high-quality Two Piece rigid box design North Carolina” that resonate with the local business community. This is the crucial step of this Custom Rigid Boxes Obtaining Guide,

Work closely with the manufacturer’s design team. Many local experts provide free design consultation and mockups within 1-3 working hours of receiving your brief. You steer the design process, share inspirational ideas, and get instantaneous feedback. Here, a design revision might only add 5-10% to the overall cost while giving a custom rigid boxes finish that adds real value to your products.

5. Material Selection and Sustainability Options

Select materials that combine durability with sustainable practices. Ask manufacturers if they use eco-friendly papers and sustainable inks. Today, many North Carolina packaging manufacturers choose greener alternatives; for instance, over 45% of local companies’ report using sustainable materials to reduce their carbon footprint.

When you compare material options, consider both the quality of the board and the finish quality. Some providers offer specialized coatings that improve box longevity and tactile appeal. Use keywords such as “eco-friendly custom rigid boxes North Carolina” when researching. By choosing sustainable materials, you not only support the environment but also cater to an audience that values green business practices.

6. Order Process and Lead Time Management

Streamline your ordering process to avoid delays. Start by selecting your design, finalizing your artwork, and then reviewing a digital proof. Manufacturers often report production lead times within 12 days. You must confirm each detail promptly and maintain open communication with your supplier.

A typical order process follows these steps:

- Initial Consultation: Share your design ideas and requirements.

- Price Quotation: Receive a quote within 1-3 working hours.

- Artwork Submission & Approval: Upload your files for a digital mockup.

- Final Production: Confirm the order and track the progress online.

- Shipping & Delivery: Enjoy fast, reliable delivery within the stated lead time.

This hands-on ordering process helps you stay on track with your timeline. Even better, each step adds clear direction, which lowers the chance of mix-ups or confusion along the way.

7. Customer Support and Quality Assurance

Make sure the manufacturer gives strong customer support and follows strict quality checks. Also, check if they offer clear digital proofs, safe packaging, and shipping with tracking. Ask them to explain their quality process in detail so you know what to expect.

Many local manufacturers in North Carolina are proud of their great after-sales help. A lot of vendors follow up with customers and ask for feedback to keep getting better. By talking with support teams early, you build a strong base for a smooth project. Things like quality alerts, timely updates, and even fast help during problems show that the manufacturer meets your high business standards.

Conclusion

For better results, you can use the local advantages—such as superior production efficiencies, competitive pricing models, and sustainable practices—to elevate your brand. Now that you possess detailed insights and exact numbers, approach manufacturers with confidence and steer your project to success.As you walk through each step, remember that simplicity, clear communication, and local insights make all the difference. Local suppliers not only set high production standards but also deliver a personal touch that transforms your packaging into an extension of your brand identity. Embrace this NC Custom Rigid Boxes Obtaining Guide as a tool that enlightens every aspect of your purchasing journey, from budgeting to design to after-sales support.

FAQs

Can I get free design support for my custom box project?

Many suppliers provide free basic design support or artwork consultation. However, you might pay an extra fee if you need a custom design developed from scratch. Most agreements include free design revisions within a set period.

What is the Other Name of Rigid Box?

They are also known as setup boxes. You can use them for luxury products. At the same time, they are ideal for high-end retail items.

What is the difference between a folding carton and rigid box?

- Material & Strength: Rigid box uses thick and strong paperboard. However, folding carton uses thin and light paperboard

- Assembly: A custom printed rigid packaging box comes pre-assembled and ready to use. Yet, a Folding carton ships flat and needs folding before use

- Durability: Wholesale custom printed Rigid boxes are sturdy and long-lasting. Folding carton is less strong and more flexible

- Appearance: Rigid box looks premium and high-end but a Folding carton looks simple and practical.

- Storage & Shipping: Rigid boxes take up more space but folding cartons save space and are easy to store.

How to Make Rigid Gift Boxes?

- Step 1. Prep Materials: Chipboard, decorative paper, glue, ruler, scissors, bone folder.

- Step 2. Cut Pieces: Mark and cut base, sides, and lid panels.

- Step 3. Fold Edges: Score and fold flaps up.

- Step 4. Assemble Frame: Glue flaps inside walls; hold until set.

- Step 5. Wrap Outside: Glue and smooth decorative paper around.

Step 6. Line Inside: Glue plain paper or fabric inside; let dry.