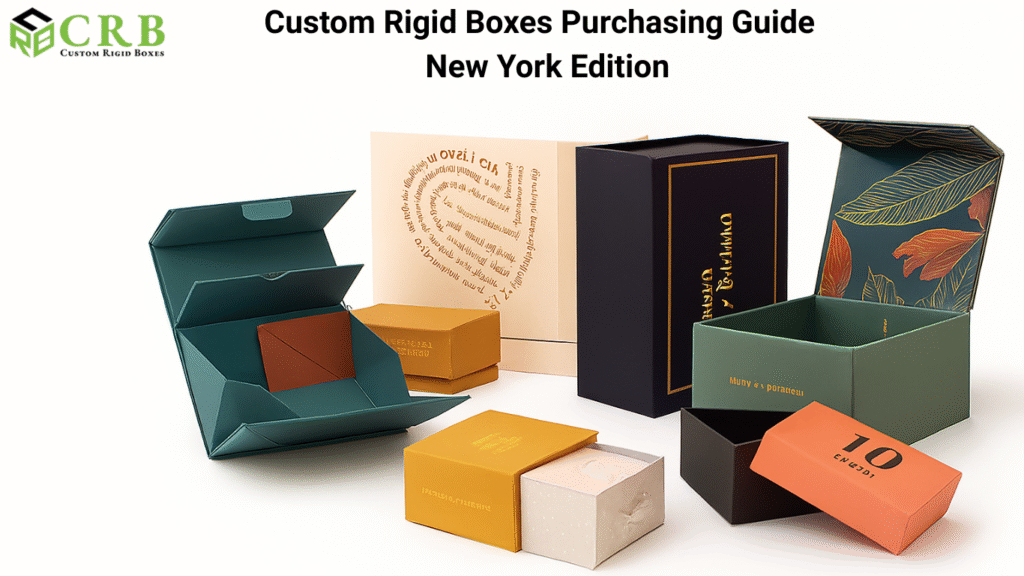

Do you know how to buy custom printed rigid packaging boxes wholesale? If not, then this Custom Rigid Boxes Purchasing Guide can serve you. New York remains a center of innovation, and its businesses demand packaging that reflects their quality and edge. For this purpose, custom printed rigid boxes wholesale help tell your brand’s story.

The city hosts over 19 million residents and drives trends that power a booming packaging industry with growth rates reaching 25% year-over-year. To grow sales and brand identity, designers offer exclusive options such as Personalized premium rigid packaging for cosmetics to appeal to eco-conscious consumers.

With over 523,000 business establishments in this US State, how can you buy boxes that can distinguish your brand and products among others? Let’s explore how they can transform your branding and protect your products and examine a complete Custom Rigid Boxes Purchasing Guide for New York Businesses.

What Are Custom Rigid Boxes?

These boxes truly stand out in the world of packaging. They arrive already put together, made from strong chipboard or thick paperboard. This gives your product great protection while also making it look high-end.

Even better, you can shape these boxes to fit your exact design ideas. Choose your own colors, textures, and special finishes. This flexibility lets you match the box to your brand and product perfectly.

As soon as a customer opens the package, they notice the difference. The look and feel of the box leave a strong first impression. That moment helps build trust and adds real value to the product inside. For example, many companies choose Luxury rigid box packaging for electronics because it boosts product appeal and reassures buyers with a polished look.

Key features include:

- Sturdy Construction: Built to protect fragile items.

- Customization Options: Tailor shapes, sizes, and designs.

- Elegant Finishes: Achieve high-end looks with foil stamping, embossing, or soft-touch coatings.

NYC Custom Rigid Boxes Purchasing Guide

These boxes hold up well during shipping and grab attention right away when shown in a store or opened at home. To help you choose the right packaging boxes, follow this simple and practical guide to know how to buy custom rigid boxes in New York.

- Initial Consultation: Clarify your packaging needs, design ideas, and expected quantities.

- Design & Prototype: Work with the supplier to develop a design and review prototypes.

- Approval & Production: Finalize the design and set the production timeline.

- Delivery & Feedback: Receive your boxes, inspect the quality, and share feedback.

Consider the flowchart below to visualize the process:

| Step | Action | Timeline |

|---|---|---|

| Consultation | Set objectives and design brief. | Day 1-2 |

| Design & Prototype | Create sample boxes for review. | Day 2-3 |

| Approval & Production | Confirm design and commence production. | Day 4-6 |

| Delivery & Follow-Up | Receive final order & evaluate fulfillment. | Day 7 onward |

In this busy city market, quick steps make a big difference. That’s why many local businesses finish orders in just 7 to 12 days, helping them stay on track with customer needs.

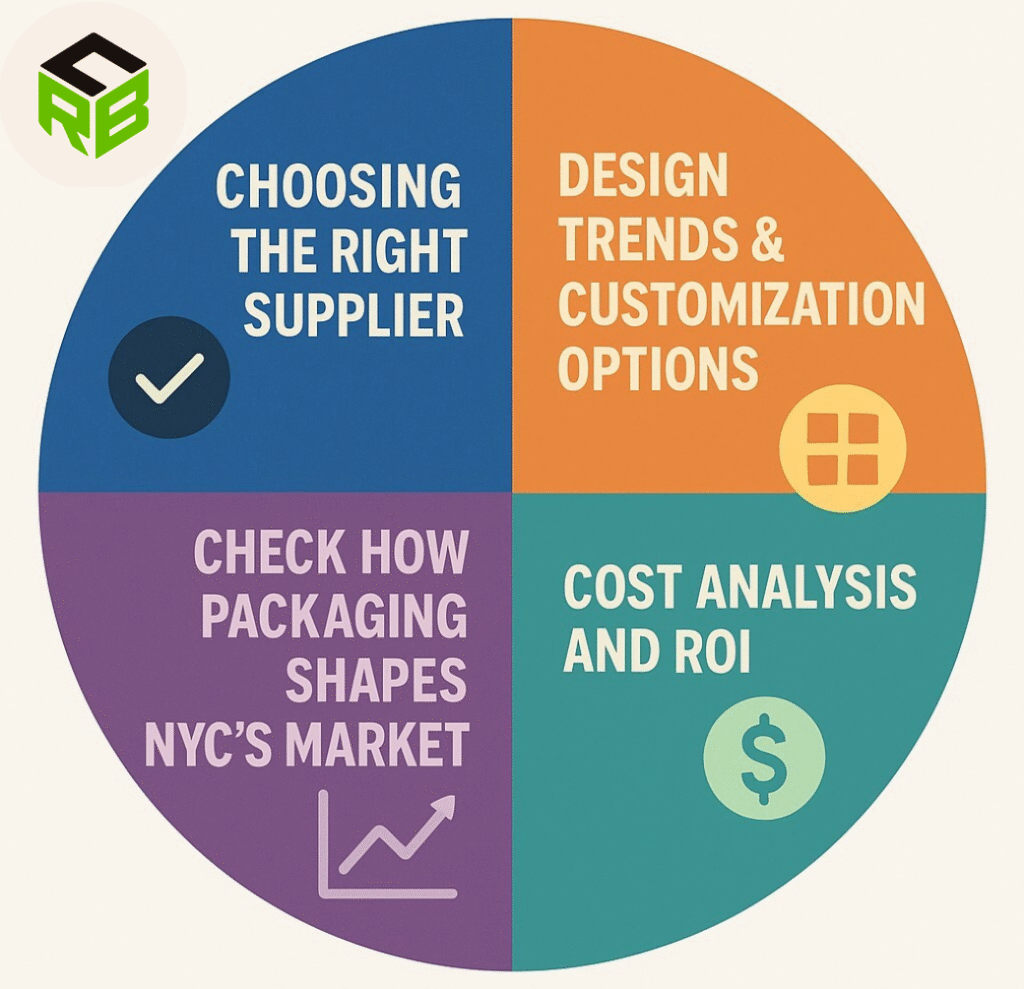

Choosing the Right Supplier

New Yorkers demand efficiency, consistent quality, and reliable delivery. When you choose a supplier, focus on these criteria:

- Quality and Customization: Ensure the supplier offers diverse materials and finishes.

- Expertise and Credibility: Look for suppliers with a strong local track record and positive reviews.

- Production Speed: Benchmark data shows that 78% of NYC merchants value quick turnaround times.

- Local Support: Suppliers with local offices offer easier communication and faster problem resolution.

Use the checklist below to evaluate each supplier:

| Criteria | What to Look For |

|---|---|

| Quality & Customization | Variety in thickness, finishes, and printing options. |

| Experience | Proven track record in the New York market. |

| Turnaround Time | Orders completed in 7-12 days. |

| Customer Service | Active support channels, including live chat and phone. |

Making the right choice can create a long-term partnership that drives your brand forward.

Design Trends & Customization Options

Design trends in 2025 favor minimalism and sophistication. Companies use them to tell a story that distinguishes them from competitors. Expect to see these trends:

- Clean Designs: Simple yet elegant designs allow your product to shine.

- Bold Typography: Your brand name and key messages stand out and grab attention.

- Innovative Closures: Smart closure systems enhance both functionality and style.

- Eco-Friendly Materials: More companies choose sustainable options to match consumer values.

Many retailers now choose Custom collapsible rigid boxes for retail to save space while maintaining an upscale look.

The table below highlights key trends alongside market figures:

| Trend | Adoption Rate in NYC | Notes |

|---|---|---|

| Clean & Minimal Design | 65% | Preferred by a majority of creative brands. |

| Bold Typography | 55% | Enhances brand recall and visual impact. |

| Innovative Closure Systems | 40% | Includes magnetic and snap-fit designs for easy access. |

| Eco-Friendly Materials | 85% | A must-have for modern, sustainable businesses. |

Additionally, premium clients incorporate Magnetic closure rigid boxes for luxury gifts to enrich their unboxing experience. New York’s fast-paced market embraces these exciting trends to keep brands ahead of the curve.

Cost Analysis and ROI

Investing in quality packaging delivers measurable returns. These packaging solutions might carry a higher upfront cost, but the enhanced image and customer satisfaction drive 30% increased repeat business. Let’s break down the numbers:

| Cost Factor | Details | Impact |

|---|---|---|

| Unit Cost | Higher quality materials mean higher cost. | Premium feel and durability. |

| Customization Fee | Extra for unique finishes and embellishments. | Boosts brand identity. |

| Bulk Discount | Lower unit price for larger orders. | Reduces overall costs. |

| ROI on Packaging | Increased repeat business (around 30%). | Justifies the initial spend. |

It is true that brands selling high-end products often enjoy higher margins and better customer loyalty thanks to striking packaging. A clear cost analysis helps you decide on the best investment that aligns with your business goals.

From Aesthetics to Impact | Check How Packaging Shapes NYC’s Market

This tough market drives brands to keep coming up with fresh ideas. Local businesses choose these boxes for their great look and strong results. In a city that never accepts average, the right packaging speaks loud and clear.

- Market Scale: 30% of premium packaging sales arise from companies.

- Consumer Expectation: New Yorkers value standout presentation, as 70% of luxury brands in the city rely on custom packaging to drive brand success.

- Sustainability: More than 85% of New York businesses now opt for eco-friendly materials.

This dynamic marketplace proves that investing in quality packaging translates into tangible business growth.

Benefits of Buying Custom Rigid Boxes

These boxes strongly boost your brand’s look. At the same time, they stand out from the rest with clear advantages. Take a look at these key benefits.

- Enhanced Protection: They shield products from damage during shipping.

- Striking Unboxing Experience: Over 60% of customers say an impressive unboxing boosts repeat purchases.

- Elevated Brand Perception: Studies show 94% of consumers equate premium packaging with product quality.

- Reliable Durability: These boxes maintain shape even during rough handling.

The following table compares packaging options to illustrate how they stack up:

| Feature | Rigid Boxes | Folding Cartons | Corrugated Boxes |

|---|---|---|---|

| Durability | High | Medium | High (with inserts) |

| Unboxing Impact | Outstanding | Medium | Low |

| Customization Options | Extensive | Limited | Moderate |

| Premium Feel | Yes | No | No |

Conclusion

Remember, your packaging matters. In a city that never settles, distinguishing your product with exceptional custom rigid boxes wholesale in New York can provide that competitive edge. Start by looking at all your options. Talk to your suppliers and use their knowledge to help shape your ideas. They often have great advice that can make a big difference. Along the way, don’t miss any chance to adjust your design so it fits your market’s exact needs.

At the same time, if you want your packaging to look sharp and stay safe, now you have a clear path. Each step in this Custom Rigid Boxes Purchasing Guide for New York Businesses gives you a way to turn basic packaging into something that stands out. As you move forward, enjoy the process. After all, this is your chance to lift your brand with packaging that shows your focus on both quality and new ideas.

FAQs

What factors should I consider when choosing a supplier?

Evaluate customization options, production speed, local support, and quality. 78% of NYC merchants value rapid service combined with quality assurance.

How do I ensure my packaging design makes an impact?

Work closely with designers to incorporate bold elements and a unique brand story. Many brands see up to 60% of customers repurchase products when the unboxing experience impresses.

How can I craft a rigid gift box?

- Gather Supplies: Get a 2mm thick board (lined or unlined) and other needed materials.

- Prep Materials: Organize and measure everything before starting.

- Cut Pieces: Trim the board and paper to the required sizes.

- Tape Corners: Secure the corners neatly with tape.

- Wrap Box: Cover the board with your chosen paper or material.

- Add Finishing Touches: Smooth edges, clean up, and finalize the design.

What customization options do I have?

You can choose shapes, sizes, finishes, coatings, and closures. Options include embossing, foil stamping, and even unique designs like Designer rigid boxes for limited edition collectibles, all tailored to your brand’s personality.

What is the difference between cardboard and rigid boxes?

Here is the list of some differences:

- Material & Strength – Cardboard boxes are made from lightweight, corrugated material, while rigid packaging uses thick chipboard for a premium, durable structure.

- Usage & Purpose – Cardboard is common for shipping and storage, whereas rigid packaging boxes wholesale are used for luxury packaging.

- Customization & Appearance – Cardboard is simple and practical, but rigid materials offer high-end customization with embossing, foil stamping, and premium coatings.